Total asset protection

The successful painting and refurbishment of large

structures such as road and rail bridges, tank farms and other

metallic surfaces requires specialist technical knowledge,

application skills and project management capabilities.

Our expertise in anti-corrosion coatings technology has enabled the company to secure many prestigious and demanding painting contracts - including some of the largest and most iconic bridges in the country, alongside MOD warships, industrial sites and petrochemical complexes.

Turnkey management solutions include pre-survey work, through life-coatings specification, grit blasting and UHP water jetting, surface preparation and high quality coating systems application.

A full service protective coatings capability provides clients with clear advantages in project planning, control and cost - with effective safety, quality and contract monitoring systems ensuring that projects are completed on time and within budget.

Surface preparation and application of protective

coatings

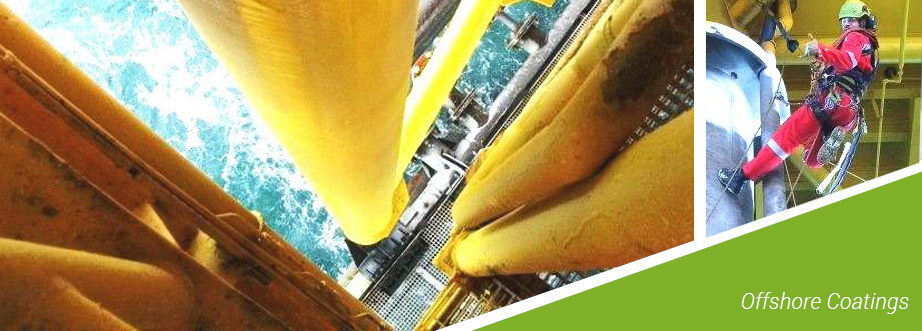

The Group provides services for the inspection, removal

and application of various coating materials which protect

equipment and facilities from corrosion and prolong the useful life

of industrial assets.

Paint materials are removed using a variety of surface preparation techniques including grit blasting with expendable or recoverable abrasives, ultra high pressure water jetting, chemical agents and mechanical abrasive machines. Paint materials are applied using airless spray units or by roller or brush in certain instances. The Group also applies thermal applied metal coatings such as zinc (metal spraying) using electric or gas arc heating equipment to provide corrosion protection.

Painting and coating work is recurring in nature, with customers regularly inspecting, evaluating and replacing the protective coatings on their facilities. A typical protective coatings project starts with some form of surface preparation followed by the application of a coating system chosen to perform against specific requirements. For example the application of thermal applied zinc or to glass flake paints would be specified where protection of the asset is required in heavily corrosive environments such as oil rigs in the North Sea or Royal Navy warships.

Intumescent (fire protective) coatings may be specified where structural integrity of the steel structure is to be assured in the event of a fire, (periods of protection can vary from 30 minutes to 2 hours). Other specialist products such as paints that reduce the radar signal of warships, or paint that maintains ships underwater hull free from marine growth, leading to increased speeds for warships and significant saving in fuel, may be specified depending upon the asset concerned and its proposed usage and lifecycle.

Wide ranging experience

Bridges and other waterway structures, MOD and commercial marine

vessels, tank farms, petrochemical plants, railway system

infrastructure, offshore facilities, wind farms

Comprehensive technical support

Coatings surveys and analysis, coatings specification development,

assessment of hazardous or toxic substances, annualised cost

programmes

Accreditation

Qualified under Industrial Coatings Applicator Scheme (ICATS),

approved by Correx Ltd and Institute of Corrosion, fully accredited

to National Highways Sector Scheme 19A

Full support services

Encapsulation and environmental protection, traffic management

systems, industrial cleaning systems, structural refurbishment,

concrete repairs, fire sentry services, naval stealth systems