Contract Scaffolding

Wood Group Industrial Services Limited is an established

supplier of full turnkey access and scaffolding systems. Innovative

and cost effective design solutions meet the demanding access and

technical requirements of a wide range of projects in the

construction, marine, transport infrastructure and civil

engineering sectors.

An active member of the National Access and Scaffolding Confederation's Technical Committee, we have extensive expertise in the design, supply, and installation of all forms of access, containment and enclosure systems that meet the highest safety standards as well as complying with all regulatory and environmental controls.

A wide range of systems is provided:

• Traditional tube and fitting systems

• System scaffolding

• Temporary formwork/falsework and roofs

• Lightweight and Kwikform systems

• Bespoke access systems

• Rope Access

The Group designs, erects, hires and dismantles temporary

scaffolding structures that allow access for ongoing maintenance,

inspection, periodic scheduled shutdowns, capital improvements and

emergency repairs. The vast majority of scaffolding services are

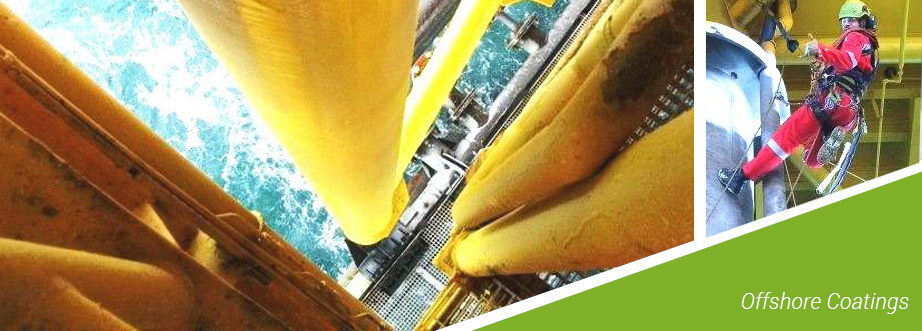

performed on large, complex industrial sites, ships, oil rigs,

bridges and pipe networks.

The Group designs the scaffolding or temporary access works to be

erected, provides skilled labour for the erection and dismantling

the scaffold and inspects such structures to ensure no unauthorised

adaptions have been made and the temporary works structure

continues to provide a safe working platform.

Wood Group Industrial Services Limited maintains stocks of

'system' and 'tube and fitting' type scaffolds to enable a wide

range of structures to be accessed in the most cost effective and

safe manner. As at 31 December 2012 the Group owned scaffolding

with an estimated replacement value of £8.3million. In addition to

traditional scaffolding services, the Group provides other

specialist work access solutions such as rope access or mobile

erected work platforms.

Much of the Group's equipment is located at customer sites and it

is often erected and dismantled repeatedly as a part of the ongoing

maintenance of a customer's facility or as part of providing access

for an engineering project

Health and safety

The highest health and safety standards are maintained. These

include IOSH approved training courses; development of method

statements, safety plans and risk assessments for all contracts;

regular site audits and detailed safety inspections by qualified

personnel.

Project management

Industry standard systems are in place to ensure the consistent

and reliable availability of all project planning data, logistical

information and client reports.

Design and innovation

In-house design solutions and a directly employed workforce allows

the delivery of standard and complex access solutions in a cost

effective and timely manner.

Quality Control

Our management procedures ensure full compliance with BS EN ISO

9001 accreditation. Access operations are accredited to the

management standards of Achilles Link-Up (Proof), UVDB (Verify) and

Network Rail Principal Contractors' Licence systems.

Training

Our in-house training programmes ensure the availability

of a multi-skilled workforce capable of operating in a diverse

range of locations and industries. Specialist training modules

include working over water, asbestos awareness, railway track

safety, slinging and the operation of hydraulic access

platforms.